Search This Supplers Products:decoiler straightener feederServo roll feederDecoiler straightener feederPress feederDecoiler machinestraightener

How to setting Straightener roller

The Guide of Straightener roller setting

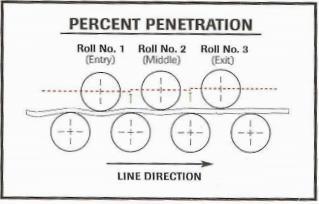

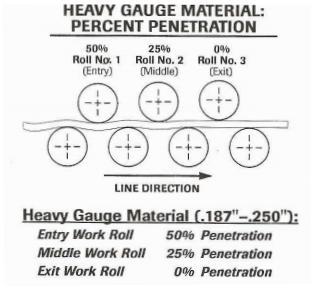

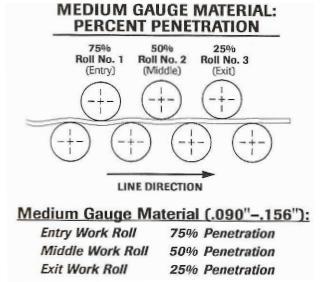

The guidelines for establishing proper work roll depth settings tend to vary as much as the potential variations in material types, thickness, and width. For the purpose of these examples we will assume the use of a seven roll straightener with three adjustable upper work rolls. The recommended roll depth setting is also referred to as amount of penetration relative to the nominal material thickness. For example, if the material is .125” thick, 100% penetration is at the zero position of the work roll, 50% penetration is at .063” above the zero position of the work roll, and 0% penetration is at .125” above the zero position. As a guideline, the first work roll should do the most straightening work, with each successive roll set to a declining amount of penetration. Regardless of the number of upper work rolls, you should be able to draw a straight line through the center of each upper work roll when the machine is initially set-up. This guideline is demonstrated in Figure

Following are some recommended starting points for straightening MCRS. Some trial and error may be required to obtain an acceptable level of flatness for your specific material. Once again, the variables of material type, thickness, and yield strength combined with the work roll diameter and center distance spacing create a wide range of potential settings.

It is important to use the minimum roll penetration which will produce an acceptable level of flatness. Excessive roll penetration will cause poor straightener efficiency, cause material to slip across the straightener, and ‘place unnecessary strain on the machine drive components. A quick visual check of the flatness can be done before the material is run into the loop area. Use the threading table or similar device to support the leading edge of the material as it exits the straightener. Fine tune the work roll settings to the minimum depth required to give the leading edge a slight upward bend. Document these settings for reference and correct set-up the next time the material is processed.