Search This Supplers Products:decoiler straightener feederServo roll feederDecoiler straightener feederPress feederDecoiler machinestraightener

What Is A "Wedge Type Structure" For Hydraulic Expansion In A Decoiler?

What Is A "Wedge Type Structure" For Hydraulic Expansion In A Decoiler?

Decoilers, also called uncoilers in some countries, are used very widely in different industries / businesses.

Whenever we use coils as our raw material, we need decoilers / uncoilers at the very beginning of the production line.

If you are looking for decoilers / uncoilers, you should read this article.

Decoiler Expansion: Manual or Hydraulic?

When talking about decoilers, the loading capacity of decoilers is very important. One of the factors that affects decoilers' loading capacity, is the expansion capacity. Manufactures of decoilers usually adopt 2 different expansion methods, taking into consideration the weight of the coils. When the coil is less than 2 tons, manual expansion is oftenly used. When the coil is over 2 tons, it's better to use hydraulic expansion for the decoilers. See pictures below to understand the difference.

Manual Expansion (Picture by: HongEr Machine)

Decoilers adopt manual expansion design when loading capacity is less than 2 tons, usually.

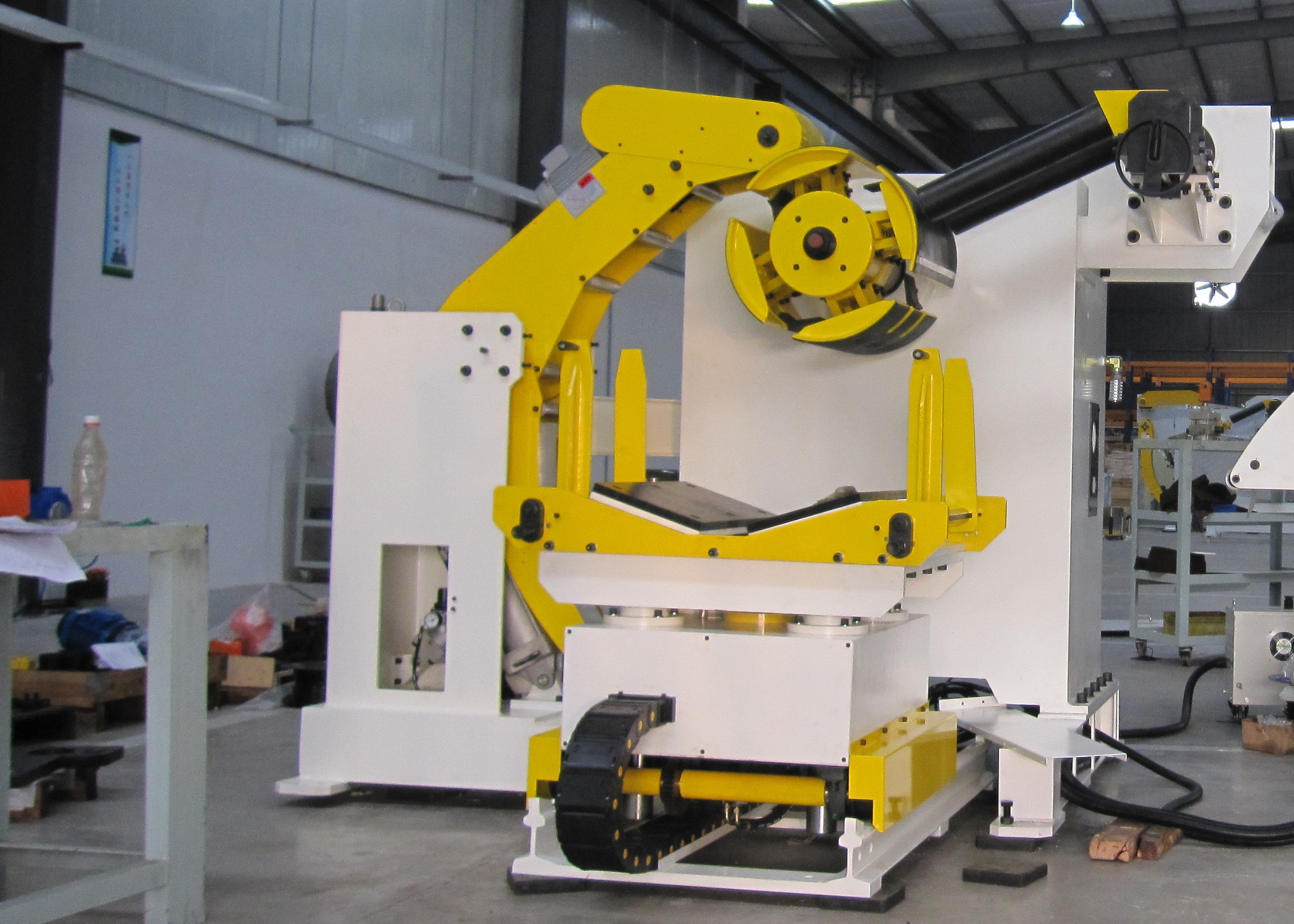

Hydraulic Expansion (Picture by: HongEr Machine)

Decoilers adopt hydraulic expansion design when loading capacity is more than 2 tons, usually.

2 Different Types of Decoiler Expansion Structures

Moreover, for hydraulic expansion, there are 2 different types of structures.

One type is "pull rod structure" expansion. And the other type is "wedge type structure" expansion. See pictures of decoilers below for the difference:

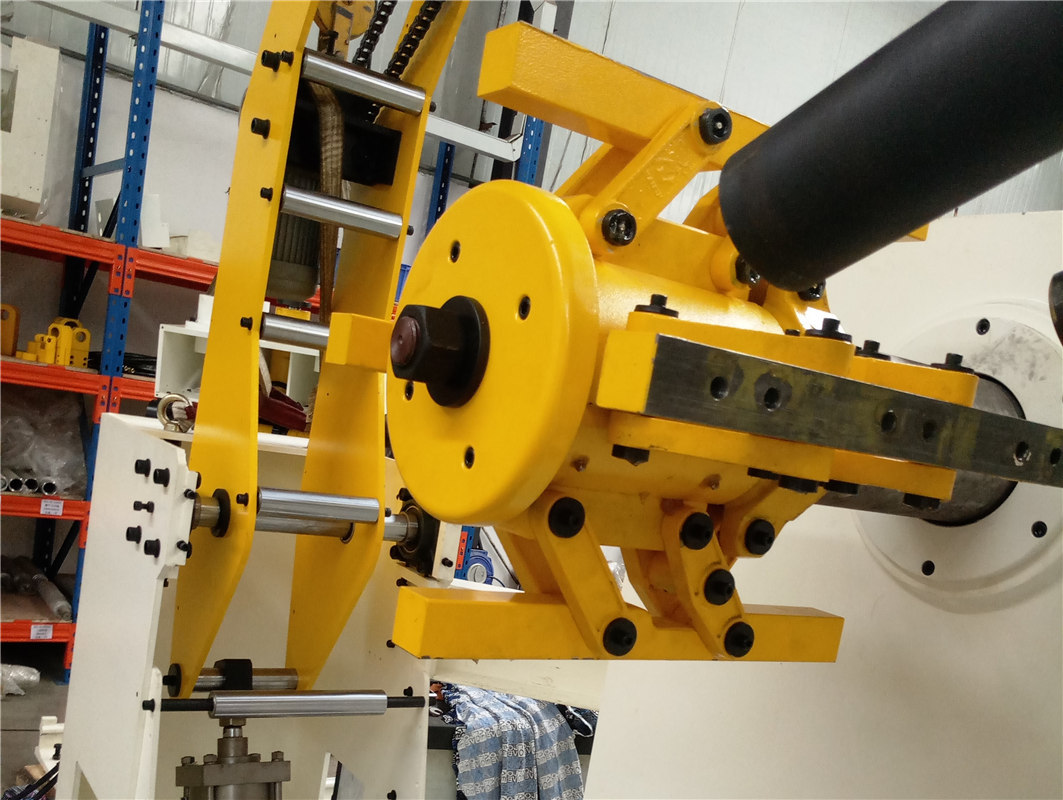

Pull-Rod Structure Expansion

See the inner structure of the pull-rod in the picture below:

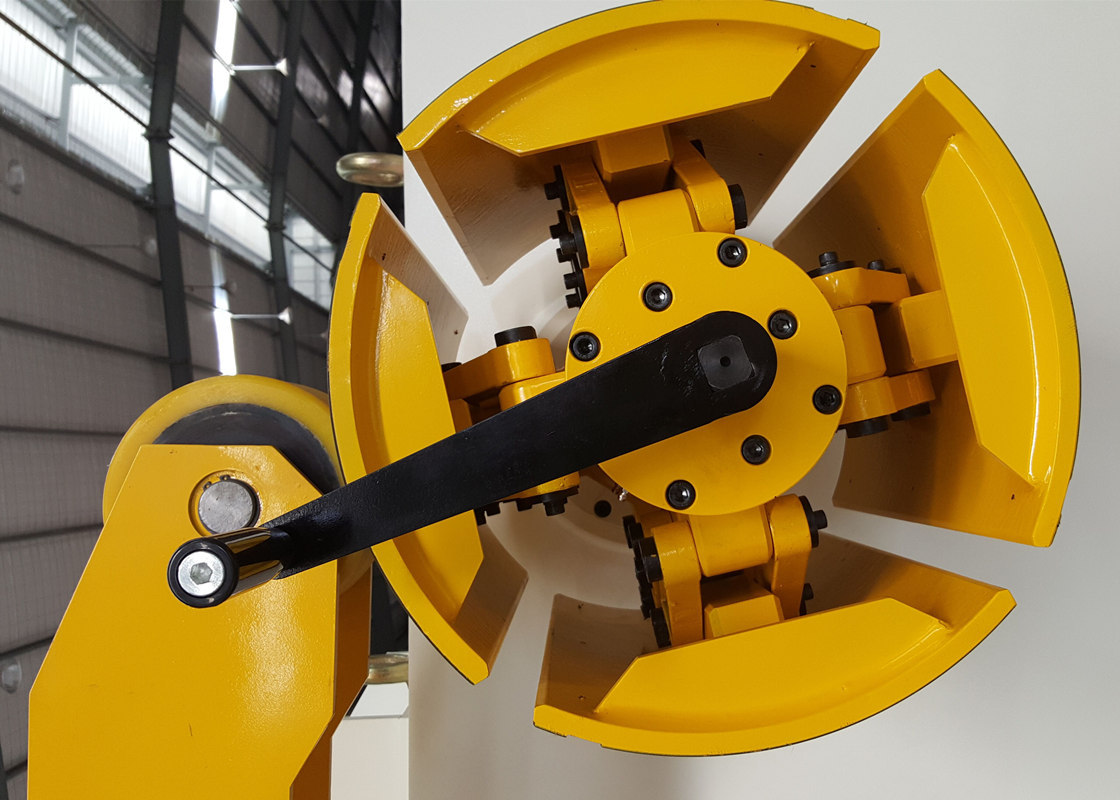

Wedge Structure Expansion

See the inner structure of the wedge in the picture below:

Details of Pull-Rod Structure Expansion

This picture is taken before a "pull-rod" type expansion decoiler is assembled. Pull-rod expansion structure is also used in manual expansion. The only difference is the power source: manual or hydraulic.

Details of Wedge Structure Expansion

This picture is taken before a "wedge" type expansion decoiler is assembled. This structure is strong and often used for the most demanding occasions.

Usually, when loading capacity is high, we use "wedge type structure" expansion for the decoilers. When loading capacity is less, we use "pull-rod structure" expansion for the decoilers. The difference for these two structures, is that the decoilers using "wedge type structure" expansion is much stronger than decoilers using "pull-rod structure" expansion. Thus, the "wedge type structure" expansion decoilers has a longer service life than "pull-rod structure" expansion decoilers.

How To Select A Good Decoiler Supplier: See Into The Details

When we sit in front of many offers from different suppliers, we get confused why the prices are so different, but the parameters are so similar. Well, the differences are in details like this. Some suppliers design their machines to be used for 1 year, some others design their machines to serve for at least 10 years.

HongEr Machine honorly choose to be the latter.

About HongEr Machine Equipment

HongEr is the leading press feeder manufacturer in China, attracting a large number of customers with high quality and perfect after-sales service. While ensuring the high quality of the press feeder, HongEr truly fulfills the promise to the customers of "ALWAYS BY YOUR SIDE" during the use process.

Selling the product is not the purpose, providing assistance to the customer and maximizing the customer's production efficiency is our constant pursuit. For all our products, we guarantee warranty, lifetime maintenance, and provide perfect after-sales service. Whether it is consulting, purchasing or repairing, HongEr has professional staff to handle it for you. You are welcome to visit our factory at any time.

Contact the author

Hazel Wu

Sales Manager

HongEr Machine Equipment

Email: hazel..........com

Mobile / WeChat / WhatsApp: +86 139 2464 3535