Search This Supplers Products:decoiler straightener feederServo roll feederDecoiler straightener feederPress feederDecoiler machinestraightener

600mm width Servo coil feeder machine process 3in1 for press punch

- group name

- Compact Servo Roller Feeder

- Min Order

- 1 set

- brand name

- HongEr

- model

- GLK4

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Mon, 13 May 2019 16:48:29 GMT

Paramtents

Decoiler Hydraulic Expansion, Motorized, Automatic

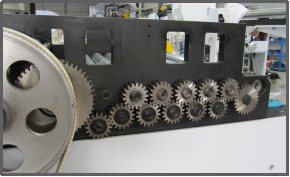

Straightener Gear drive, servo motor

Servo Feeder Yaskawa Driver and Yaskawa Motor

Oiling Machine To lubricate and cool down the coil sheet, prolongs the lifespan of dies

Shearer To cut off coil threads

Coil Weight Maximum 15 tons

Coil Width 1600 mm

Coil Thickness 0.6-6.0 mm thick

Straightener upper 4 / lower 3

Warranty 1 year

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

Coil car helps to load the steel coil. The leveling adjustment can be adjusted by hand wheels. These make the operation easy and timesaving Moreover, the combined structure also save more work space.

Model |

GLK4-400 |

GLK4-600 |

GLK4-800 |

Coil Width(mm) |

400 | 600 | 800 |

Coil Thickness(mm) |

0.6-600 |

||

Max.Coil Weight(kg) |

5000 |

5000 |

7000 |

Max.Coil O.D.(mm) | 1400 | ||

Max.Coil I.D.(mm) | 508 | ||

Max.Feeding Length(mm) | 500 | ||

Max. Speed(m/min) | 16-24 | ||

Straightener Roller(pcs) | Upper4/ Down3 | ||

Feeding Roller (group) | 1 | ||

Servo Motor(kw) | 5.5 | 7.5 | 7.5 |

Uncoiler expansion | Hydraulic | ||

Uncoiler Motor(kw) | 2.2 | 2.2 | 3.7 |

Power Voltage(V) | 220V 60HZ/ 380V 60HZ | ||

Air pressure(Mpa) | 0.49 | ||