Search This Supplers Products:decoiler straightener feederServo roll feederDecoiler straightener feederPress feederDecoiler machinestraightener

3 in 1 Compact Feeder levelling Machine with decoiler

- group name

- Compact Servo Roller Feeder

- Min Order

- 1 set

- brand name

- HongEr

- model

- GLK4

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 09 May 2019 18:18:52 GMT

Paramtents

Decoiler Hydraulic Expansion, Motorized, Automatic

Straightener Gear drive, servo motor

Servo Feeder Yaskawa Driver and Yaskawa Motor

Oiling Machine To lubricate and cool down the coil sheet, prolongs the lifespan of dies

Shearer To cut off coil threads

Coil Weight Maximum 15 tons

Coil Width 1600 mm

Coil Thickness 0.6-6.0 mm thick

Auxillary rollers Equipped

Certification CE Certificate

Packging & Delivery

-

Min Order1 set

Briefing

GLK4 Feeding the material into the press after straighting the material

Detailed

3 in 1 Compact Feeder levelling Machine with decoiler

1. Save factory space. 3 machines together in one.

2. High feeding precision: +/-0.05mm

3. Suitable for material thickness: 0.5-4.5mm.

4. Suitable for all kinds of metal coil automatic straightening and feeding, easy to operate.

5. Suitable for metal parts, electron, electrical appliance, toy and auto parts continuous pressing production, straightening and feeding.

6. Japan servo motor, PLC and other electrical parts, with little malfunction and long using time. High quality, lowest maintenance.

7. Can feed different length at the time, easy operation, safe and high stability.

8. We can customize the machine.

9. Fast speed:20m/min.

10. Coil car , pressing arm, conveyer belt , shearing machine , oiling machine etc. for choosing.

Specification

Model |

GLK4-400 |

GLK4-600 |

GLK4-800 |

Coil Width(mm) |

400 | 600 | 800 |

Coil Thickness(mm) |

0.6-600 |

||

Max.Coil Weight(kg) |

5000 |

5000 |

7000 |

Max.Coil O.D.(mm) | 1400 | ||

Max.Coil I.D.(mm) | 508 | ||

Max.Feeding Length(mm) | 500 | ||

Max. Speed(m/min) | 16-24 | ||

Straightener Roller(pcs) | Upper4/ Down3 | ||

Feeding Roller (group) | 1 | ||

Servo Motor(kw) | 5.5 | 7.5 | 7.5 |

Uncoiler expansion | Hydraulic | ||

Uncoiler Motor(kw) | 2.2 | 2.2 | 3.7 |

Power Voltage(V) | 220V 60HZ/ 380V 60HZ | ||

Air pressure(Mpa) | 0.49 | ||

Application

Metal Stamping Parts

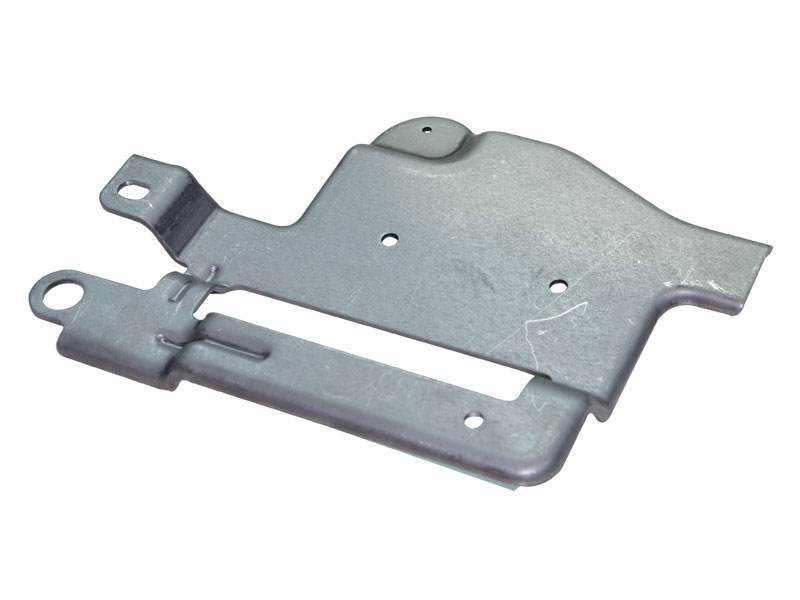

Automotive parts: Tie bar, Bracket, Damper, Brake plate.

Electrical accessory: Shell parts of printers, EI Sheet

Our Customer

3-in-1 servo straightener feeder with uncoiler machine for printer accessories production line

This is one of our customer in UK

Decoiler straightener feeder 3 in 1 machine GLK4-600 with AIDA press

Servo feeding line for SEYI Press, combined decoiler, straightener, feeder with oiling unit

This is one of our customer in Malaysia.

They produce sheet metal parts with HONG-ER coil feeding line and SEYI press machine.